Sustainability

Chilewich brings depth to surfaces.

We push the boundaries of form and function with products that combine innovative textiles and distinctive colors with extraordinary durability and easy maintenance.

Our designs can be found in the permanent collection of the Cooper

Hewitt, Smithsonian Design Museum, and in homes, workplaces,

restaurants, and hotels around the world. Discover the full collection

at chilewich.com

Life is messy.

So is sustainability. It’s a journey, not a destination. Progress, not perfection. And this can be all too easy to forget. As designers, we are challenged every day to balance beauty with practicality. This ongoing give and take provides valuable perspective, because it’s a reminder that the product and its purpose are one and the same.

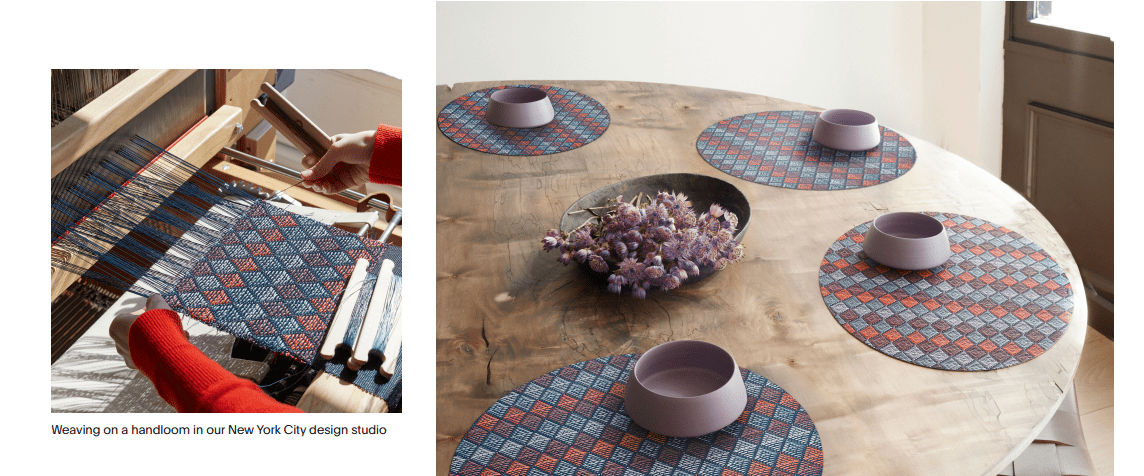

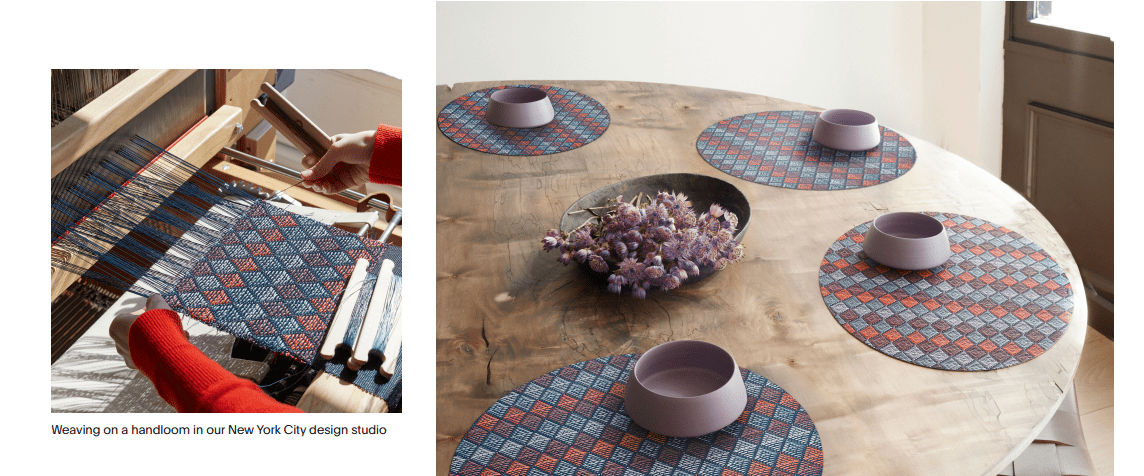

Chilewich was born in 2000 out of designer Sandy Chilewich’s passion for reimagining overlooked materials and underused processes to transform the way people around the world set their tables. In designing textiles that are not only aesthetically pleasing but also durable, versatile, and easy to wipe clean, we offer products that address a key element of sustainability: longevity. Every Chilewich product is made to endure decades of daily use and to look good doing it, while conserving the resources required by machine washing and product replacement.

Sustainability is also the quest for better, and we’re committed to continuing to make choices that are better for people and the planet. From raw materials to finished goods, design to production, we recognize that this is an evolution that encompasses manufacturers, consumers, and policymakers in a complex interplay of economics, engineering, and chemistry.

Leading with longevity.

Made to retain their refined look through decades of daily use, our

textiles are renowned for their beauty and practicality. They’re also the

product of 20 years of continuous innovation to maximize performance

and minimize environmental impact. We’re proud of the strides we’ve

made, and we’re committed to continuous improvement in our

materials and our processes

Maximizing performance. Minimizing impact

EXTENDED LIFESPAN

Strengthened by integrated antimicrobial protection, our products retain their beauty and functionality for decades, reducing energy-and cost-intensive replacement and the associated waste.

GREEN CLEANING

Our textiles can be washed with water and

biodegradable detergents.

MORE SUSTAINABLE TRANSPORTATION

Designed by Sandy Chilewich and our in-house design team, all our woven and tufted textiles are made with pride in the United States. Working with local and domestic suppliers reduces transport related environmental impacts.

FREE OF PHTHALATES AND HEAVY METALS

It all starts with the yarn. Ours are extruded, and 100% free of the phthalates and heavy metals found in conventional plasticizers.

ENVIRONMENTALLY SAFE

Our products have been tested and certified by the Green Label Plus™ and GreenGuard® programs for low VOC emissions, and they can be found in healthcare settings that include major hospitals.

ETHICAL MANUFACTURING

From carefully sourcing polymers to ensuring that our own factory in Georgia meets or exceeds EPAand OSHA standards, we take health and safety as seriously as we do innovation

Doing more with less.

We are committed to reducing waste on a company-wide basis, from

design and sampling to manufacturing and fulfillment. As part of this

initiative, we launched a zero-waste pilot program with our Fall/Winter

2021 collection. All of the collection’s tufted “Shag” floor mats were

designed to make use of surplus yarns rather than require the creation

of new yarns